Zap! How to kill pathogens in food production with UVC light

The Met Office is predicting the hottest year so far for the UK, potentially beating 2023’s record highs. And that means the food industry is at risk once more since ingredients and perishable foods are more likely to be infected by pathogens when the weather’s hot than they are under normal conditions.

So what can you do, as a player in the food sector, to keep your premises safe, your products fit for consumption, and the risk of food poisoning at bay? As it turns out, there’s a low cost, high impact way to stop pathogens in their tracks, and it’s fast becoming essential for the food industry as the climate keeps on warming.

Bacteria love hot weather

Bacteria thrive in environments of 4C to 60C and can potentially double in number in just 20 minutes. They grow faster during the summer – and during heatwaves - because of the hot and humid conditions. And that’s why there’s such a strong link between climate change and food borne infections.

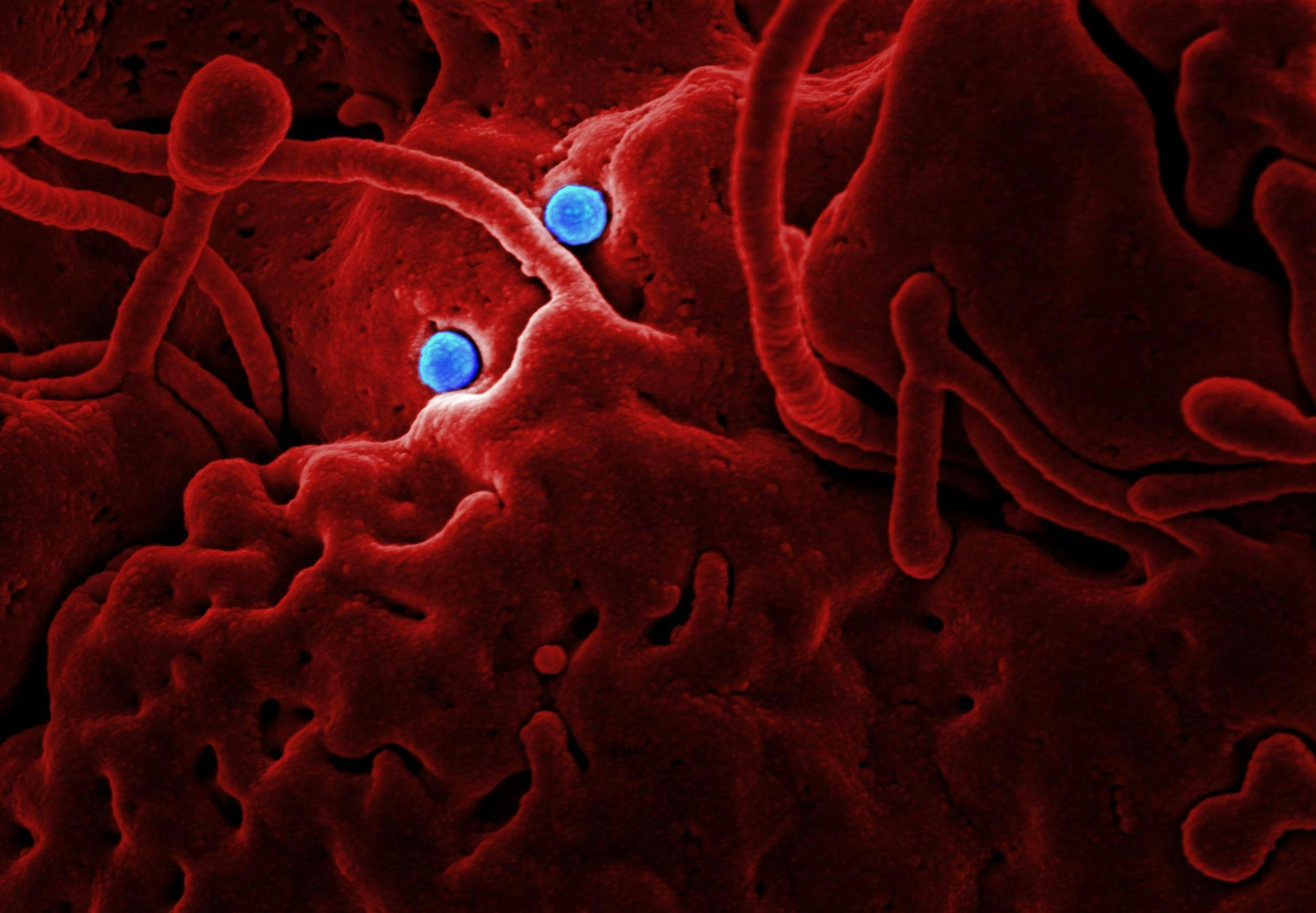

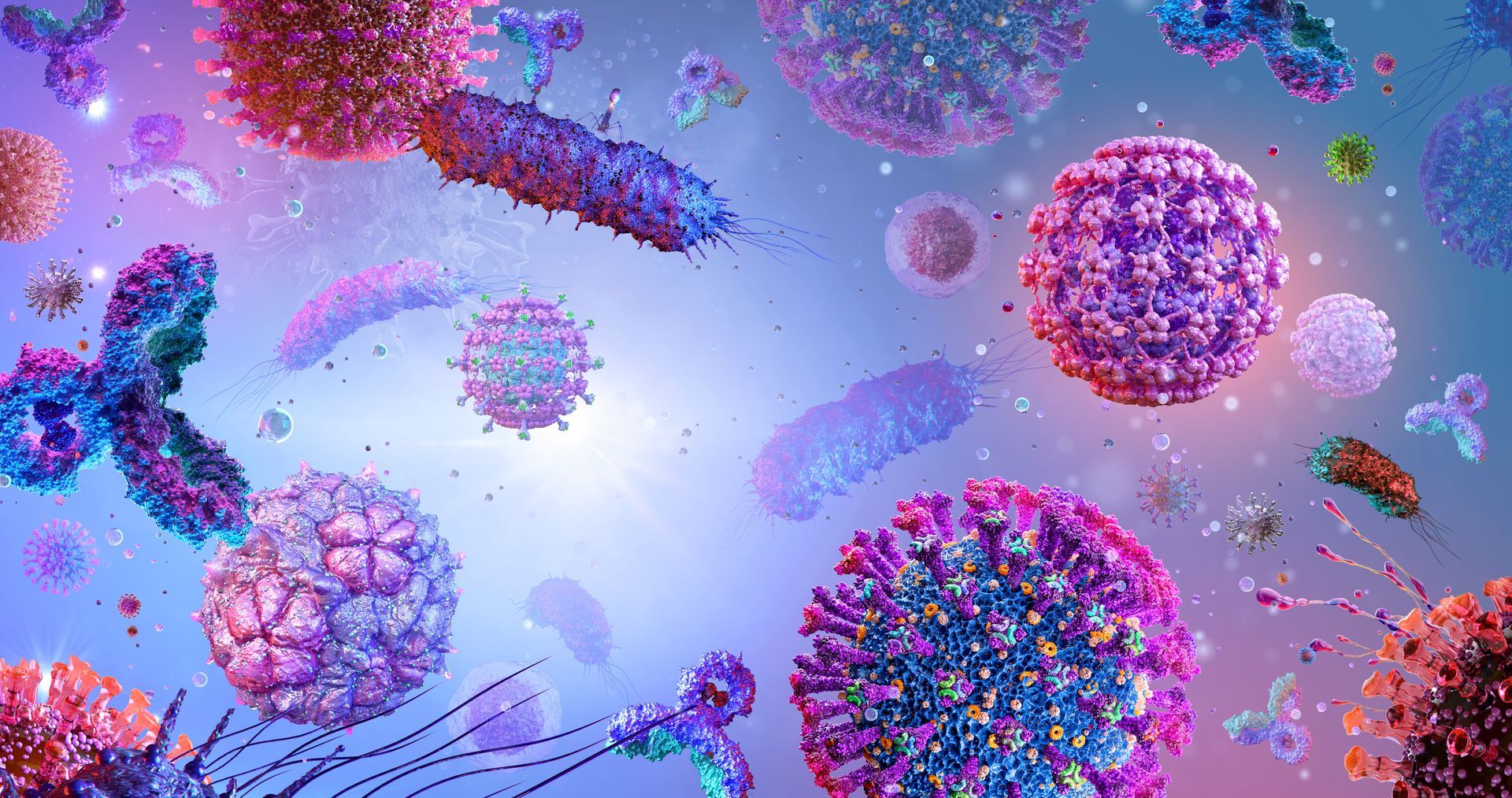

The food borne illnesses you want to control

Take Cyclospora, a tiny parasite that causes intestinal infections, transmitted through food contaminated with sewage, often vegetables and fruit. Warm weather means Cyclospora infections peak during summer along with Campylobacter, Vibrio, STEC E. coli, Cyptosporidium, Listeria and Shigella. Most cause an upset stomach, many lead to severe diarrhea, dehydration and vomiting, some people also suffer meningitis and organ failure. Then there’s the incurable Ciguatera, which turns up in imported fish. It can leave you with numb, tingling or paralysed fingers, legs and toes for years afterwards.

Mass food poisoning incidents

This year we’ve seen a mass food poisoning incident at Lewes prison in Sussex, where six people were rushed to hospital. Then Manchester City football team was hit with an outbreak of food poisoning after visiting Spain to play Real Madrid in the Champions League. We also discovered how as many as one in fifteen fresh supermarket chickens are 'highly contaminated'. Even Waitrose, known for good quality, exceeded the Campylobacter safe level target during the fourth quarter of 2023.

Safety measures like warning labels and product recalls can help slow the spread of harmful food-borne bacteria and parasites, but obviously it’s best not to end up in the situation in the first place.

Disinfect your food business fast, easily and safely at LOW cost

There’s some

remarkable cooling technology available that costs a fraction of traditional aircon, which helps keep things to safe temperature in factories and other food sector settings, but that doesn’t get rid of invisible food borne pathogens once they’ve found a way into your premises, ingredients, aircon system or products.

To kill them off before they can cause harm you need UVC light tech, which

kills a very long list of viruses, bacteria, moulds, spores and other pathogens in seconds, cleanly, safely and reliably. The tech has been used in healthcare settings for decades, proven to work and remarkably powerful.

Shine a UVC unit above your production line, for example, to keep perishable products like meat, poultry, fish, dairy, eggs and any other food that’s prone to infection safe so it doesn’t poison your customers, ruin your foodservice customers’ reputations, end up in a costly product recall, or even lead to legal action for liability.

So how do our UVC disinfecting units work?

For a start we have

a variety of units for different settings, including a brilliant in-duct air purification probe. Together our UVC purification lights, mobile sterilisers, vehicle sterilisers, ceiling purification lamps, ceiling air circulation purification lamps and surface and air purification lamps meet the needs of every food sector context, from factory to production line, sandwich shop to supermarket to deli.

The units are low cost to buy and use very little energy because they generate UVC light using cool, mercury-free LED bulbs. They’re very simple so there’s more or less no maintenance. They’re easy and safe to use. And they’re environmentally responsible, with no nasty chemicals whatsoever. Just bright, pure, powerful UVC light at a wavelength that kills pathogens in a few short minutes.

Every food business is unique, of course, so we’ll specify the perfect set-up for your premises. If you’d like to know more, contact us for a no-obligation discussion that could make your food sector life a whole lot safer no matter how hot it gets.