Ultraviolet disinfection for the food sector

Case Study

When you run a food manufacturing company or you’re in foodservice, you want to ensure your place is as hygienic as possible. In this article we take a look at how our UVC hygiene tech ups the cleanliness ante for 21st century success.

The challenge

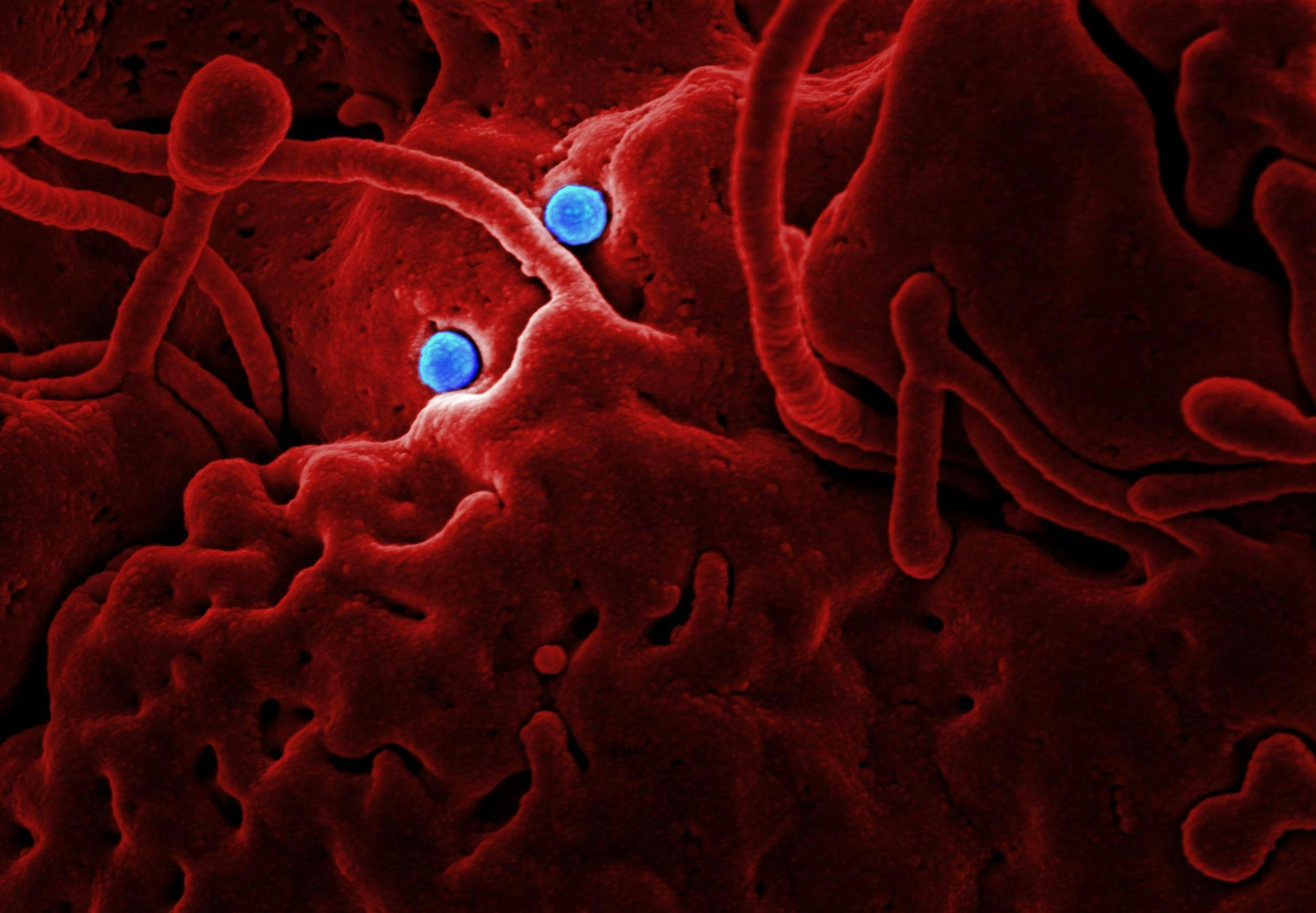

The challenge in this case was to make sure every aspect of the food production process, plus the wider office context, was protected by UVC light, which quickly kills pathogens on every surface it touches as well as disinfecting the air.

The solution

We carefully analysed the premises and recommended solutions.

For the areas where people are constantly working we suggested ceiling UVC disinfection units. They’re safe to have on at all times, constantly disinfecting the upper air that gets naturally circulated, protecting people in the vicinity.

These units are perfect for continual disinfection when people are present, in this case shared office space. The units are installed above people’s heads to stop the cross contamination of viruses and germs by reducing the viral load across the air. Basically it constantly disinfects the upper air and air from below, which is pulled through the fan to increase the circulation.

For areas where people come and go, in this case the loos, we have units that disinfect all the upper air and also feature a direct light that opens and closes when motion is detected. When the toilet cubicle is empty the light will switch on and the toilet and cubical will be disinfected. When motion is detected it will automatically turn back off.

Because ducting can pose serious hygiene issues, we recommended our CT-X4 Series disinfection lamps, installable into more or less every ventilation duct. Germicidal Ultraviolet lamps fitted in ventilation ducts help protect people from harmful airborne micro-organisms including bacteria, moulds, viruses and Legionnaires Disease.

We also suggested a mobile UVC LED germicidal light as the perfect complement to regular cleaning by humans. There’s no downtime and a very fast turnaround. The units are designed for easy, efficient use. They can easily be moved from building to building and room to room either for constant disinfection or to respond to a hygiene emergency. We have a 200W and 600W version, and in this case the 600W version was ideal.

The impact

Food businesses are becoming increasingly concerned about the food poisoning outbreaks seen recently in the UK. They’re keen to keep their employees healthy and at work, not on sick leave. They want to manufacture food that’s safe, tasty, and risk-free for consumers. And they want to avoid the financial problems that come with product recalls, close-downs and reputation damage.

Our units help food sector companies do all of this. They use very little electricity thanks to efficient, long-lasting LED bulbs. And there’s barely any maintenance.

The cost of this successful UV disinfection project?

- The cost to supply and fit 6 upper air UVC disinfection units: £3450

- To supply and fit 6 motion sensitive upper air UVC disinfection units: £14,250

- To supply and fit a germicidal UV lamp to each of 4 ventilation ducts: £1735

- To supply one 600W mobile UVC disinfection unit for use by the cleaning team: £8450

Protect your future with powerful, hard-working UV sanitisation

So how about your business? If you’d like to minimise sick days taken off because someone spreads their cold or flu or covid around the premises. If you want to stay safe from legal action over making consumers ill. If you want to build your reputation as the best and keep it that way.

If you want to maximise your potential and minimise food hygiene-led risks... let’s talk.