How data transparency supports reliable UV LED covid disinfection

Disinfection against covid is absolutely crucial, now and into the future. So far UVC LED technology is the best, most efficient way to disinfect spaces against the virus. To ensure the technology is properly understood throughout the supply chain, and widely trusted by the public, it is vitally important to be completely transparent about the data behind ultraviolet LED. Here’s what you need to know. Thanks to

LEDs magazine for the insight.

Disaster and innovation go hand in hand

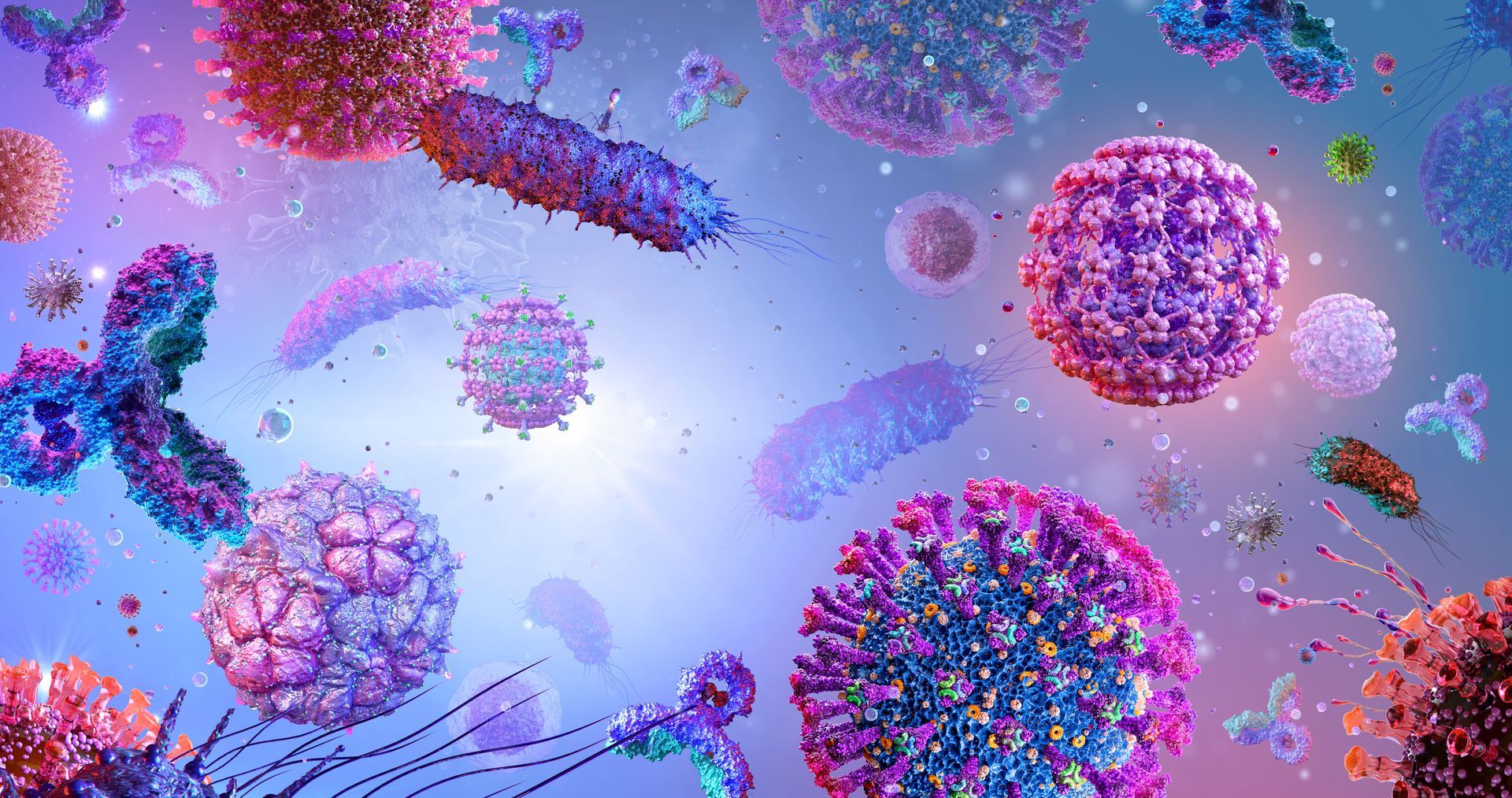

Strife drives innovation. It happened during the First World War, where we saw the arrival of marvels like sun lamps, tea bags, and zips. The pandemic is driving the same kind of innovation, with fast-changing and fast-developing new technologies emerging, coined to help us cope with a worldwide emergency. One example is the rapid advances in ultraviolet C-band (UV-C) LED technology for viral disinfection.

Germicidal UV brings some brilliant opportunities to humanity, but there are also some challenges around openness to deal with. The last thing our sector needs is to risk jeopardizing the adoption of germicidal UV, or even threaten public safety. It’s important since we’re already seeing misinformation spreading about the use of hand-held home UVC devices, manufactured by unscrupulous makers, which can be very dangerous as well as ineffective.

Every piece of data matters

All the characteristics of an LED must be provided, otherwise the information is incomplete. If a manufacturer talks about radiant flux without mentioning input power, what are they hiding? If you know the dosage but have no clue about the efficiency data, you’re missing crucial insight. A wavelength on its own doesn’t mean much. And if you make a lifetime claim without temperature data, the information means absolutely nothing.

WPE - All about wall plug efficiency

Wall-plug efficiency describes the ratio of radiant flux to input power. UV-C LEDs are relatively new tech, and the WPE is low compared to old-school mercury-vapour lamps. There’s also a significant WPE variance between LED manufacturers, sometimes as much as two times at much the same power level. Luckily, thanks to today’s outstanding rates of progress, it won’t be long before LED WPE overtakes the old mercury vapour tech.

LED facts – The truth about radiant flux

‘Radiant flux’ describes the radiated energy an LED gives out at a specific input current and voltage. It’s really important to compare like for like, and that means understanding the total power at which the flux is stated. Many manufacturers provide the radiant flux, or the radiant flux at a given current, but there’s a problem here. All UV LEDs are not equal. The VF or forward voltage varies dramatically across manufacturers, from as low as 5V to more than 8V at 350 mA.

How many nanometres? It’s a wavelength thing

254 nm is only one of the choices available right now. UV-C LEDs range from 220–280 nm, and some are already commercially available. The point is, the shorter the wavelength, the lower the flux, efficiency, and lifetime of the LED. It’s another thing everyone needs to know about.

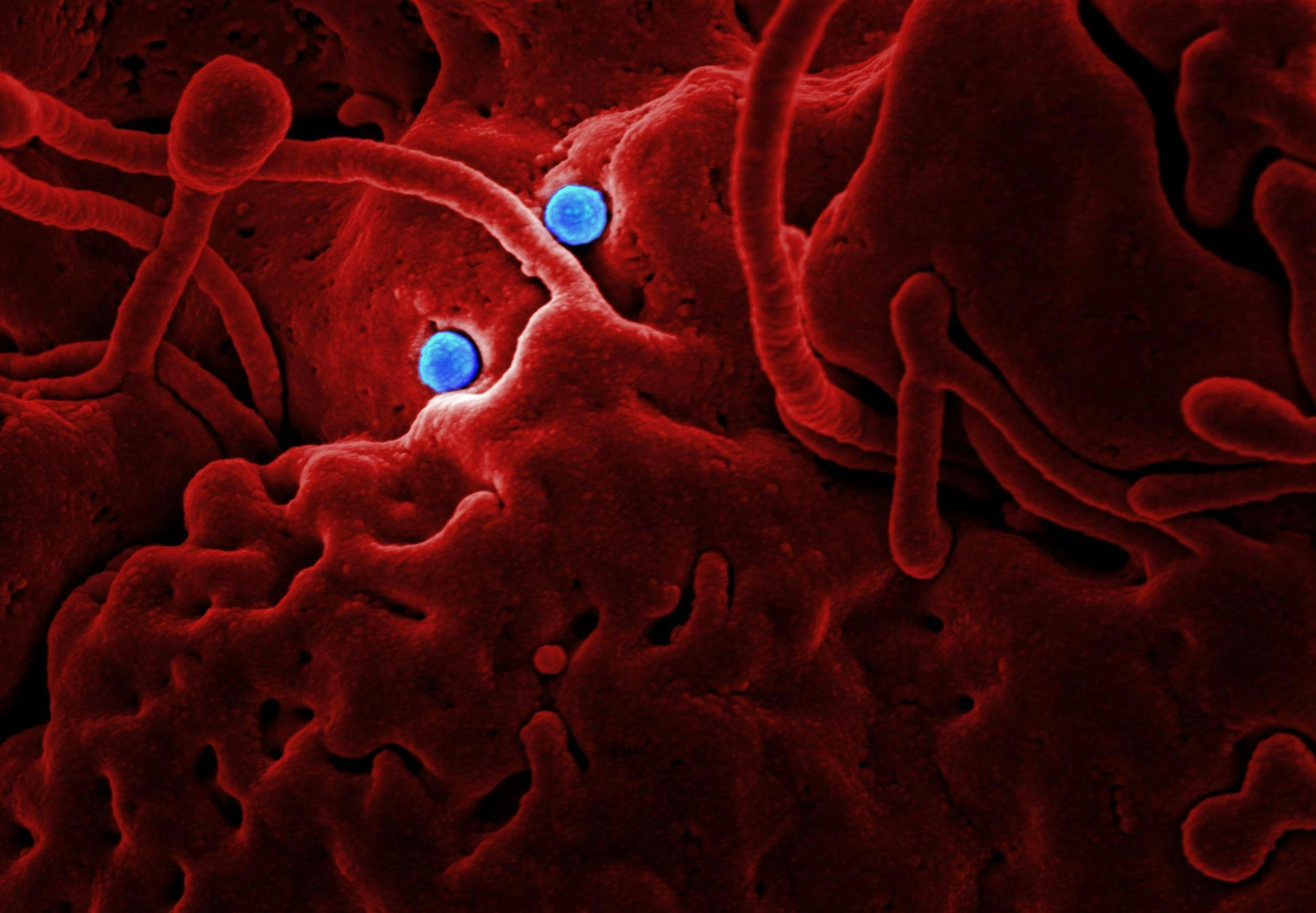

Kill that virus! What about virucidal power?

Virucidal power describes the virucidal efficiency multiplied by the radiant flux. Virucidal efficiency versus wavelength obviously matters when you want to kill a virus. But that isn’t the only side of the story. It looks as though 265 nm is probably the most efficient germicidal inactivation wavelength, assuming there’s the same radiant flux per wavelength... but sadly that doesn’t quite work, simply because radiant flux varies according to the wavelength. Although the wavelength is fixed for each LED engine, they can come in a variety of wavelengths. Two wavelength engines mixed in the same array makes them even deadlier, as the pathogen DNA damage would differ slightly for each wavelength type. Virucidal power is most suited to UVC LED light sources.

The facts around junction failure

Junction temperature occurs at the junction of the LED die, where the electrons collide to create light particles/waves called photons, plus heat. LEDs and heat don’t go together well, which means this junction is absolutely critical when talking about LED output and lifetime.

System dose insights

It’s a shame that dosage sharing hasn’t been happening over the past year or so, since the pandemic hit.

To figure out the required system dose you need to multiply the irradiance in mW/cm2 by time in seconds, and experts are going as far as calling the secretive nature of dosing a ‘very irresponsible tactic’. There has been a multitude of claims around covid inactivation but very few of them have mentioned the actual dosage. Every system should come with clear information about the dosage and efficiency, rather than making spurious marketing-led claims like ‘disinfects in seconds’.

The lifetime of LED tech

LEDs don’t usually fail dramatically, they tend to gradually fade. Lifetime hours are described by manufacturers as Lxx, with xx being the percentage of radiant flux left. Heat is the biggest reason LEDs degrade, but few if any manufacturers bother to include this in their lifetime data. Accurate lifetime data must also include the junction temperature, the only way for users to properly understand LED lifetime in a thermally-stable system.

An appeal to every LED manufacturer on the planet

As key players in the LED UVC disinfection sector, we’re appealing to LED manufacturers to openly provide every piece of information needed. At this stage in the pandemic, and going forward, sharing is not just ‘nice to have’. It’s essential.